Filter In Hydraulic System

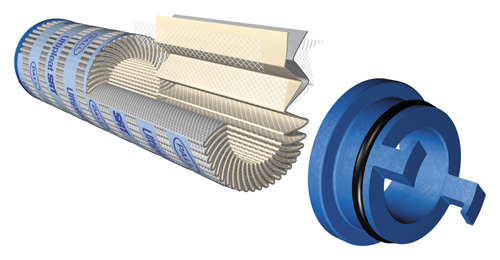

Filter in hydraulic system. A filter is a screening or straining device used to clean the hydraulic fluid preventing foreign particles and contaminating substances from remaining in the system. This filter is generally installed between the pump outlet and the rest of the components in a hydraulic system. Typical contaminants found in hydraulic systems are sand silica silt metal oxides carbon and even air.

Aircraft Hydraulic System Filters. A hydraulic filtration system includes hydraulic filters to remove dirt and particles on a continuous basis. During normal operation wear and tear of the valves pumps and other components cause tiny particles of metal to break off and go into suspension in the fluid.

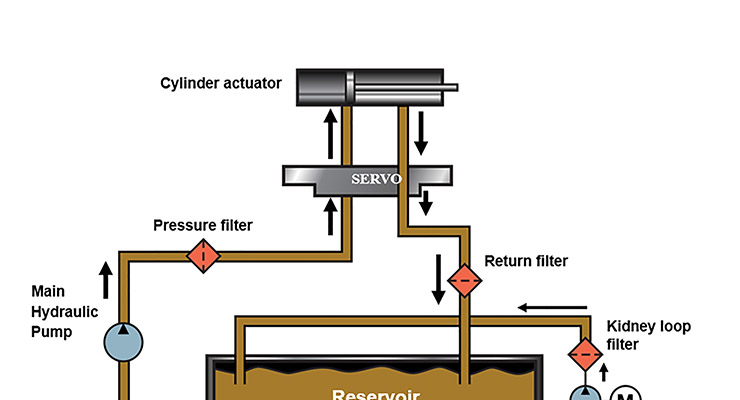

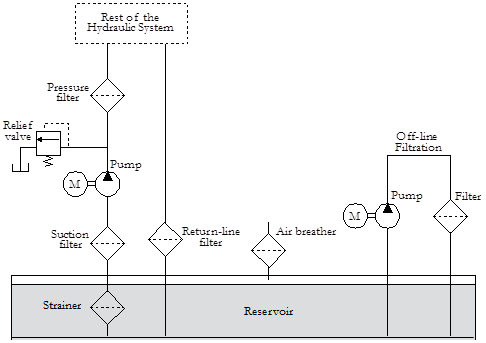

Hydraulic filters are used anywhere in a hydraulic system particle contamination is to be removed. The purpose of such a system is to actuate a hydraulic cylinder also known as a hydraulic motor using pressurized hydraulic fluid. In the old days a 10-micron filter was used to protect a system without servo valves but there was no measurement for how efficient the 10-micron filter was.

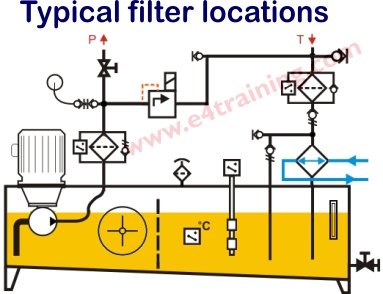

Most owners and operators of hydraulic equipment will not get the opportunity to choose where their filters are placed in a system. Figure 1 If such objectionable material were not removed the entire hydraulic system of the aircraft could fail through the breakdown or. Soft particle pollution paint film.

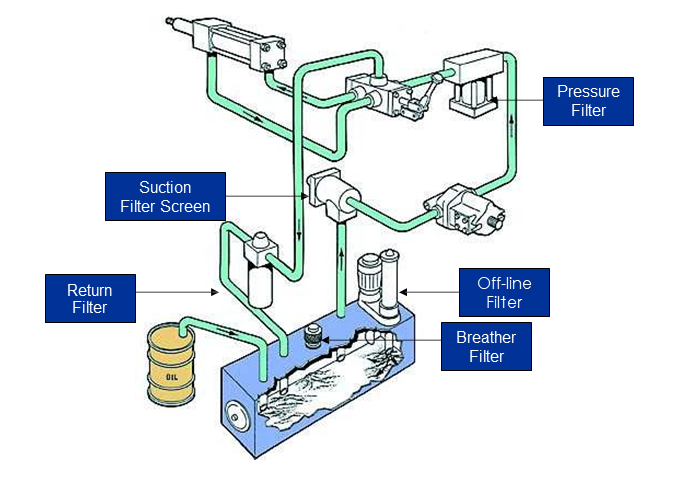

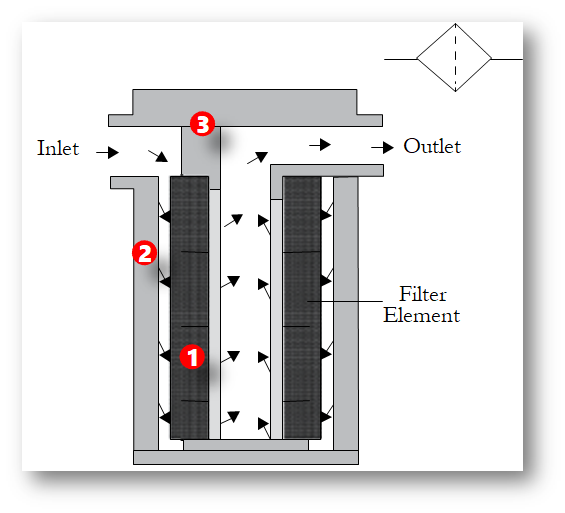

The performance for every hydraulic filter is measured by its contamination removal efficiency ie. There are a several types of filters including. Hydraulic filters remove contaminants from oils emulsions and other hydraulic fluids.

A basic hydraulic system consists of several components. Our Team Will Help You Choose the Right Product for Your Application. The bag filter consists of a cloth bag which the hydraulic fluid is pushed through the contaminants being solid are unable to flow through the bag as well.

A filter is necessary in a hydraulic system to remove any foreign particles or contaminating substances from the system. The terms suction filter and suction strainer are often used interchangeably but their main difference is the size of the contaminants they remove.

During normal operation wear and tear of the valves pumps and other components cause tiny particles of metal to break off and go into suspension in the fluid.

Aircraft Hydraulic System Filters. Return filters may be installed either in-line or inside the reservoir in-tank return filter. T he pollution of hydraulic oil means that the hydraulic oil contains impurities such as water air solid particles chemical substances and microorganisms. Soft particle pollution paint film. Suction filters and strainers are employed in hydraulic systems to remove contaminants from process fluids. The purpose of such a system is to actuate a hydraulic cylinder also known as a hydraulic motor using pressurized hydraulic fluid. During normal operation wear and tear of the valves pumps and other components cause tiny particles of metal to break off and go into suspension in the fluid. Hydraulic filters keep the hydraulic fluid contaminant free. A filter is necessary in a hydraulic system to remove any foreign particles or contaminating substances from the system.

Typical contaminants found in hydraulic systems are sand silica silt metal oxides carbon and even air. A hydraulic filter helps to remove these particles and clean the oil on a continuous basis. Maintained hydraulic filtration plays a key role in machine preventative maintenance planning. However a key success factor for hydraulic systems is maintaining fluid cleanliness in order to optimize function. The idea here is to protect all components in a given system. A filter is necessary in a hydraulic system to remove any foreign particles or contaminating substances from the system. Filtration Fact The function of a hydraulic filter is to clean oil but the ultimate purpose is to reduce operating costs.

Post a Comment for "Filter In Hydraulic System"